This post contains affiliate links.

In this installment of the Shopsmith refurb series, we take start the process to bring it back to life.

Now that I have my ShopSmith home and taken apart, it’s time to start with the real fun. Each part gets cleaned before putting it all back together. Along the way, I’ll make an improvement or two and tell you why.

The Frame

I started with the legs and bench tubes. Brushed all the dust and dirt off the legs and caster assemblies, then took a rag dampened with a little bit of mineral spirits to cut through any grime. Then it was on to the bench (bottom two) and way (top two) tubes.

With the way tubes raised up and pinned in the vertical position (learned very quickly to screw in the pin – ouch!), I used some WD-40 and 320-grit wet/dry sandpaper to clean up the bench tubes. Once I was happy with the way they looked, I moved up to 600-grit and sanded them smooth again.

After lowering the way tubes back into the horizontal position, I repeated the process I used on the bench tubes with them. When I finished, I wiped all four tubes down with mineral spirits to cut the lubricant. I waxed both pair of tubes with MinWax paste wax. I’d have used Johnson’s but Minwax is what I have.

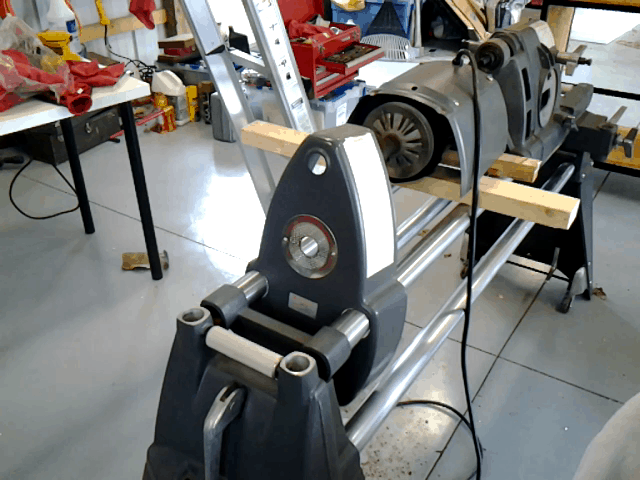

The Headstock

Each part that’s been removed gets dust brushed off and any grime or old oils removed with mineral spirits and a rag or brush as the case may be. I used steel wool to remove the surface rust on the inside of the headstock cover, then “washed” with mineral spirits. Once evaporated, I sprayed some clear lacquer on the inside to seal it from further oxidation. Next, I removed the motor from its pan and gave the pan the same treatment. I made sure to clean all the bits and bobs that go in the headstock before moving on to…

The Quill

There was a good amount of gunk in the teeth of the quill. I brushed it out with a brass brush and took some mineral spirits to the whole thing. Once the leftover mineral spirits evaporated away, I gave it a quick polish with some wax. I took the opportunity to wax the inside of the headstock where the quill passes through just to make sure it would move freely.

Everything Else

A little mineral spirits, a rag, and a brush takes care of cleaning up all the other parts. I gave the work table the same treatment as the tubes: 320 grit paper, then 600, mineral spirits, then wax. I used a flat board as a backer for the sandpaper so I wouldn’t leave high and low spots. After cleaning each of the tables; work table, extension table, and two floating tables; I gave each of them a coat of wax to help keep the rust at bay.

Now that all the parts are clean, they’re ready to reassemble. With a little luck, it will go back together almost as easily as it came apart.